Advantage Depth: Crealights Technology has released two new high-quality transmission optical fiber cables

03/01

2022

At the 2022 Beijing Winter Olympics, the 8K ultra-high-definition ground display system provided by BOE complemented the highly anticipated giant "snowflake". With a contrast ratio of 100,000:1 and a refresh rate of 3840Hz, it presented an ultra-high-definition and dazzling picture with a resolution of 29900x15096.

A picture of willow branches expressing emotions is not only the ultimate display of Chinese romance, but also a visual feast presented by 8K ultra-high-definition display technology.

Behind the world's amazement at this splendid scene, the 8K HDMI2.1 high-definition data cable responsible for transmission has played a significant role!

Recently, Crealights Technology has released two active optical fiber cable products, namely HDMI 2.0/2.1 active optical fiber cable and USB3.0 full-function hybrid optical fiber data cable.

As an upgraded product of traditional copper wire cables, the active optical fiber cables launched by Crealights Technology feature large transmission capacity, good transmission quality, low loss and long relay distance.

Five major advantages of optical fiber cables over copper wire cables:

● Large capacity: The operating frequency of optical fibers is 8 to 9 orders of magnitude higher than that of cables, so the developed capacity is large.

● Low attenuation: The attenuation per kilometer of optical fiber is more than one order of magnitude lower than that of the currently largest-capacity communication coaxial cable.

● Good anti-interference performance: Optical fibers are not affected by strong electrical interference, electrical signal interference or lightning interference, and also have a strong ability to resist electromagnetic pulses.

● Save non-ferrous metals: Generally, communication cables consume a large amount of non-ferrous metals such as copper, lead or aluminum. Optical fibers themselves are non-metallic. The development of optical fiber communication will save a large ● amount of non-ferrous metals for the country.

● Easy expansion: A standard fiber optic dedicated line with a bandwidth of 2Mbps can be easily upgraded to 4M, 10M, 20M, 100M or even G bandwidth.

Why did Crealights Technology venture into the field of high-definition adapter cables?

Ren Zhengfei has mentioned in many speeches that Huawei's long-term strategy is to never blindly innovate away from tradition, but to open up and innovate based on its existing existence.

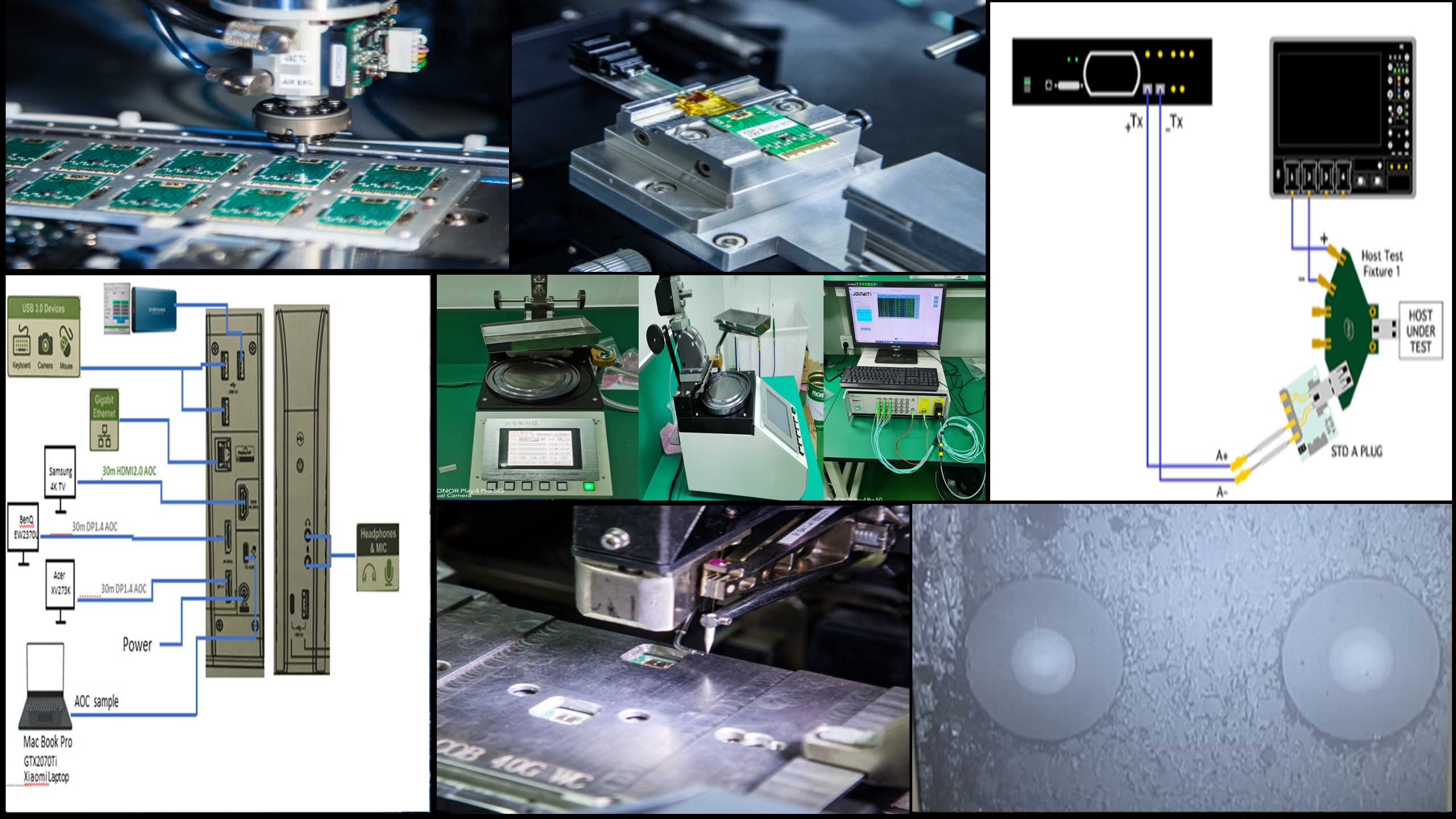

The innovation strategy of Crealights Technology is no different. For over a decade, Crealights Technology has been dedicated to high-speed data transmission optoelectronic products. Relying on its independent innovation and R&D capabilities, it has established an intelligent and automated vertical integration platform covering chips, components, and optoelectronic products. Based on common technical platforms, manufacturing processes, and packaging and testing methods, it can rapidly develop and mass-produce various product forms according to different application scenarios. Thus, in the fields of data/signal transmission (transmitting end) and data/signal processing (receiving end), a deep competitive barrier has been established.

Especially in recent years, based on the Wafer In-Module out silicon photonics packaging and testing platform independently built, Crealights Technology has further seized the initiative in the core of high-speed optoelectronic interconnection - chips, providing a complete set of solutions for the production of HDMI-type high-speed optoelectronic interconnection products, laying a solid foundation.

The three major platform advantages of Crealights Technology

Silicon photonic wafer chip platform

Crealights Technology has developed a silicon photonics wafer-level inspection and back-end processing platform with independent characteristics. Wafer-level inspection of silicon photonic chips is of great significance for reducing the costs of later chip inspection and packaging and increasing the production rate of modules. Currently, commercially available wafer-level automated testing equipment is relatively expensive and has certain customization features. In the future, it will take a considerable amount of time to upgrade and transform the software and hardware for silicon photonic wafers of different specifications. In response to this, Crealights Technology independently developed a silicon photonic wafer inspection system with certain distinctive features compared to the industry. This system includes multiple functional modules such as motion control, precision calibration, optical detection, and electrical detection. This system features autonomy, ease of software and hardware modification, low cost, high precision (50nm), and high efficiency.

From silicon photonic wafers to silicon photonic chips, they still need to go through processes such as thinning and dicing. Grinding the back of the wafer to a certain thickness has the advantages of improving the heat dissipation efficiency of the chip, reducing the volume of the chip package, and reducing the stress on the back. Crealights Technology has currently developed a wafer thinning process, with a thinning accuracy that can reach ±5μm. Wafer thinning is next procedure after the wafer cutting, namely the scribing. The accuracy of dicing determines the distance between the optical coupling port and the solder pad in the chip and the edge of the chip, thereby affecting the performance of the chip such as coupling insertion loss and high-frequency bandwidth of wire bonding. In order not to reduce the performance of the chip after packaging as much as possible, Crealights Technology uses laser invisible cutting technology - by focusing the laser on the inside of the silicon wafer to form a modified layer, and then separating the chip by means of expanding the film. It features no pollution, no material loss, high processing efficiency and high processing accuracy (< 3μm). In addition, in order to enhance the performance of the chip after coupling and meet the demand for higher transmission rates, Crealights Chips has also developed process technologies such as chip flip-chip and silicon V-slot etching.

The Crealights Technology silicon photonics platform provides high-quality and customizable chips for HDMI and other cable products, thus ensuring that the performance of optical fiber cables reaches the best state to a certain extent.

A mature semiconductor process platform

Crealights Technology has mature semiconductor manufacturing process capabilities. Based on multi-channel parallel optical process technology, an automated process from surface mount technology (SMT), wire bonding to multi-channel optical coupling has been established. In the cable assembly stage, a full touch screen grinding machine, 24 OE grinding discs, optical fiber IL&RL inspection instrument and optical fiber grinding end face inspection instrument are configured, thus ensuring independent button control of the single-step program. After being equipped with corresponding fixtures, various connector products can be ground. The 24-hole OE ferlet dedicated grinding disc is suitable for grinding consumer-grade AOC optical ferlets. The IL&RL tester and the optical fiber end face detector ensure the grinding performance and consistency of optical fibers. Adopt fully automatic Haba welding to increase production capacity and ensure welding quality and consistency. Introducing the traditional copper cable injection molding process further enhances the feasibility of mass production of AOC and reduces the cost of cables. During the testing phase, different types of testing environments are customized according to different AOC application scenarios. Crealights Technology possesses consumer-grade AOC protocol testing and analysis capabilities, as well as BER testing capabilities in high and low temperature environments, which can better manage the potential failure risks of products. It is equipped with high-precision resistance testers to ensure the welding quality of wires.

Crealights Technology's mature semiconductor manufacturing process platform ensures the quality of wires from every step of the production process. Through large-scale equipment and user tests, as well as repeated accelerated aging tests in the laboratory, problems such as incompatibility in use have been effectively resolved.

One hundred thousand class dust-free workshop equipped with modern enterprise operation platform

Crealights Technology has built nearly 10,000 square meters of dust-free workshops and established a vertically integrated process manufacturing platform based on automation and informatization, which is at the international leading level, covering the packaging and processing of optical devices and optical communication products. The platform is equipped with a mature MES+ERP+PLM modern enterprise production and operation management system, which can adapt to different external product forms. According to different application scenarios, through common technical platforms, manufacturing processes, packaging and testing methods, etc., it can achieve flexible production planning management, quickly respond to customer demands, and stably realize large-scale product production.

Crealights Technology has launched high-quality cables, which is another innovation based on its existing advantages in the high-speed interconnection market field after its optical module products have fully penetrated the global data center market and served the world's mainstream Internet enterprises. With this, Crealights Technology has officially opened up a new development pattern in the consumer high-definition transmission market.

At present, 4K ultra-high-definition smart terminals are in the stage of universal popularization, and the 8K ultra-high-definition industry is also being continuously promoted due to the accelerated development of 5G. In the future, the Crealights Technology series of cables will provide high-quality signal connections for gamers and home theater enthusiasts to enjoy clearer and smoother images.

Recommended Reading